Home > INDUSTRIES > Solution >

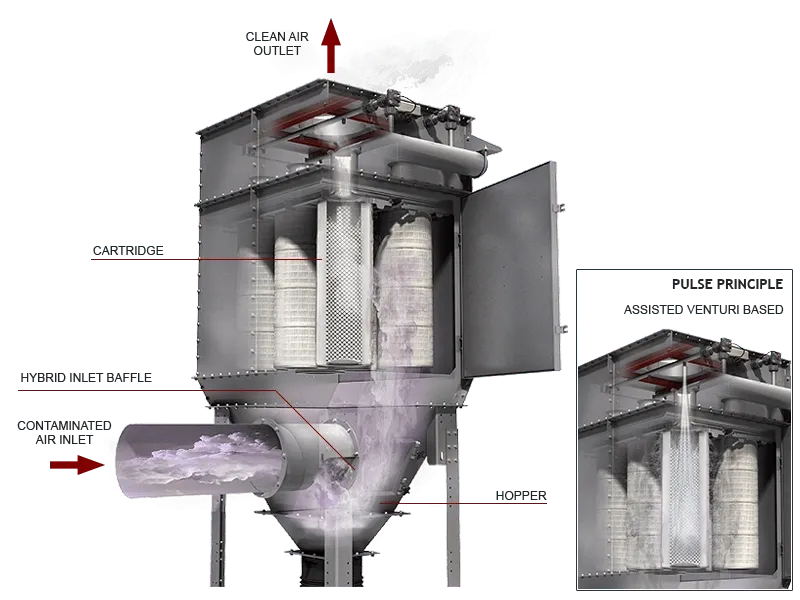

The cartridge dust collector is currently the dust removal equipment with relatively high dust removal efficiency in China. The filter element, injection valve, and control system are all made of qualified

products. The filter cartridge adopts the polyester peritoneal burning method to become a micro filter. The efficiency of filtering sub-micron particles can be as high as 99.99%. The compressed air is

back-blown to restore the filter material. The control system adopts a human-machine interface, which can realize Fully automatic control.

The design of the filter cartridge dust collector, from the downdraft structure of the downflow box to the simple access door, strives to simplify its maintenance, making the replacement of the filter

cartridge safe, faster and easier. Because the dust removal unit has a long service life and excellent dust collection and cleaning capabilities, it can run for a long time. However, when the filter cartridge

needs to be replaced, it can be disassembled and replaced quickly, easily, and even without tools.

Technical features of cartridge dust collector:

1. The interior adopts a special pleated filter cartridge for pulse, which has a compact structure and saves space.

2. The filter cartridge has good sealing performance, is easy to install and replace, and shortens parking time.

3. High filtration efficiency. For powder with an average particle size of 0.5 micron, the filtration efficiency can reach 99.99%.

4. Save compressed air consumption. Compared with conventional pulse dust collectors, the injection pressure can be reduced by 20%.

Cartridge dust collectors are widely used in welding, casting, metal cutting, metal grinding, wood processing, papermaking, ceramics, tobacco, chemicals, electronics, polishing, steel, electricity, organic

material cutting and grinding, dyes, food and other fields .

Realated products recommend