Home > INDUSTRIES > Solution >

Background of dust control in power industry:

At present, the types of dust collectors mainly include electrostatic precipitator, bag filter, wet filter and cyclone filter, among which electrostatic precipitator and bag filter are widely used, while wet filter and cyclone filter are relatively limited. The working principle of electrostatic precipitator is to use high voltage electric field to ionize the flue gas, and the dust charge in the air flow is separated from the air flow under the action of electric field. The negative electrode is made of metal wires with different cross-section shapes, which is called discharge electrode; the positive electrode is made of metal plates with different geometry shapes, which is called dust collecting electrode. In recent years, China's electrostatic precipitator has achieved rapid development and wide application, the number of production and use of electrostatic precipitator ranks first in the world. Moreover, ESP is still the absolute mainstream of ultra-low emission dust removal equipment in coal-fired power plants. According to the statistics of China electricity Union, up to now, ESP has a market share of 66.4% in the power industry.

Description of the dust control plan for the power industry:

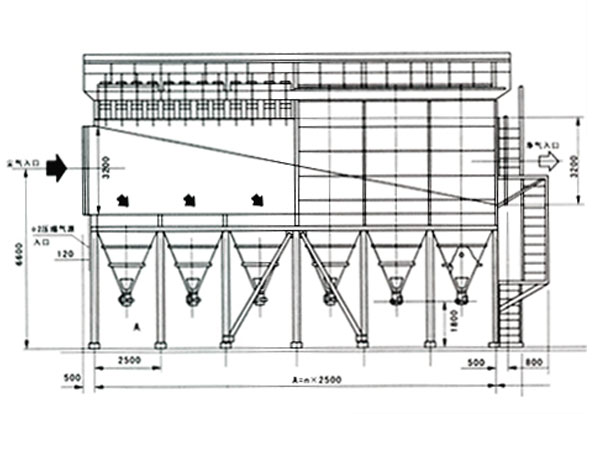

Bag dust removal for coal-fired boilers is a key environmental protection equipment for power generation enterprises. Our company transformed the electrostatic precipitator into a bag filter, removed the power supply system of electrostatic precipitator, did not change the original structure of the electrostatic precipitator shell and the inlet and outlet smoke box, recombined inside the original electrostatic precipitator, and carried out the original three-layer porous air distribution plate. It is reorganized to become a dust pre-separation device, which solves the problems of unburned coal particles abrasion and burning of the filter bag. In order to achieve a higher emission standard, zero leakage of the clean air chamber is realized, and no leakage of the bypass valve is realized. The bag filter of the power plant adopts a compartment positioning back blowing mechanism and an automatic tensioning device. It has a simple structure and reliable operation. When the filter bag is cleaned, the back blow air flow is used, that is, the dynamic cleaning principle is changed, and the static cleaning is realized, thereby improving the filtration. Bag service life. The dust removal equipment of coal-fired power plants adopts the divisional positioning bag dust removal technology. Unlike other domestic manufacturers introducing and digesting foreign technology, this technology is better than foreign pulse dust removal technology in the filtration, dust removal, and protection of the bag filter. There are obvious advantages. The filter bag protection is more optimized, the ash cleaning system is greatly simplified, the operating reliability of the unit is significantly improved, the operating cost is greatly reduced, and the price is only half of foreign products. It is a major invention developed by my country and suitable for China's national conditions. From design to product localization.

Introduction to the control effect of the dust control plan in the power industry:

1. The ash discharging method of ash bucket, ash discharging car, spiral discharging device, etc. can be selected;

2. Imported PLC is used to control adjustable pulse blowback, and there is no pressure difference indicator;

3. The equipment has high purification efficiency; it has a purification efficiency of more than 99% for dust with a particle size of more than micron;

4. The equipment is energy-saving, the running resistance is 500-800pa, the initial resistance is less than 200pa, and the highest resistance is 1500pa; (determined according to the wind pressure of the system fan.)